Successful Partnerships on QCS - Profiler Expertise : A Case Study

Successful Partnerships on QCS - Profiler Expertise

Paper quality and paper machine production efficiency have become more important key elements in the success of any paper mills in recent years. Automatic machine-direction controls (MD-control) and developed on-line quality measurements (QCS) are almost a standard on all paper machines worldwide. Nearly as often,today's paper machines are equipped also with an automatic profile control (CD-control), minimum for basis weight. This is because a good and controllable basis weight profile creates the base for many other paper properties, it reduces the number of web breaks, broke and improves machine runnability. It also affects significantly the downstream process fluency.

In the Indian paper industry, the development and increase of automation level has lately been very fast, even faster than many other paper-manufacturing countries. Requirements for paper quality and the demand for the quality of the equipment used to control paper machine, have changed in India strongly. Today the selection between the control systems is not based on price only. Reliability, high quality and long lifetime are now more important criteria when a supplier for automatic control equipment is decided. The cost of lost production is often many times higher than cost of a good automatic control system.

Automatic basis weight profile control can be implemented in two different ways. Either by controlling headbox slice opening with motorized slice lip actuators or if a headbox is provided with a dilution system, the basis weight profile control is done by adding dilution water into the stock by using dilution valves and - actuators. In both cases, the first precondition for functioning control is of course a reliable and accurate on-line QCS measurement, which can identify basis weight variation in CD and MD direction and is also capable to separate these variations from each other. Secondly, the system must have intelligent control algorithms, which can do accurate and adaptive mapping, can make control actions in the right extent and right moment. Finally, the system must include precise mechanical actuators, which are executing the control actions.

Traditional and high-quality on-line measurement and quality control system supplier in India is Jasch Industries. Jasch has delivered QCS systems for more than 20 years. They have hundreds of such successful systems installed in India and worldwide including Europe & South America which is impressive evidence of market acceptance.

Jasch systems are designed to be rugged for a paper machine environment but at the same time simple & easy to maintain and focus on the most important task of high accuracy measurement. The design philosophy has been minimum maintenance with maximum performance.

Tasowheel Systems is a very traditional profile control actuator manufacturer in Finland. Their devices represent nearly an industrial standard when talking about products used to control the paper machine profile. During the 40 years of operation, they have delivered well over 200.000 profiling control actuators and valves all over the world. Tasowheel portfolio includes systems for basis weight, moisture and coating profile control. Tailored solutions for a motorized and manual slice - and dilution actuators, dilution valves, steam box, and re-moisturizer actuators and also coating actuators are always based on customer's needs.

Manufacturing a profile control actuators requires a lot of know-how, as they have to operate 24/7. The challenge is even higher as actuators must be100% available tens of years with low - or no maintenance. This is the ability that Tasowheel has learned over the years and is separating them from other actuator manufacturers. The most important precept in company's actuator design, material selection and in manufacturing itself has always been high quality and thus long lifetime and reliable products. Many paper mills have Tasowheel actuators controlling their paper profile already decades in very harsh conditions often with no service or scheduled maintenance.

Jasch Industries and Tasowheel have agreed of a co-operation in which the division of responsibilities follows the strengths of the companies. Jasch scope includes reliable and accurate on-line measurements, QCS scanner and MD & CD controls and Tasowheel provides actuators and valves. Systems are integrated so there is no need for a hardware – or software interface that would distinguish them to be separate systems. Jasch can communicate with Tasowheel actuators directly,no PLC or PC based black box needed to connect the systems. From outside it is really like one system only, also projects are implemented with one contact person principle. Since the co-operation started Jasch – Tasowheel has already had several projects together -most of them in India. Customers have been invariably satisfied to results of this collaboration. In India, an additional advantage is a locality, communication with own language and help is always very close.

Often in paper machine rebuilds an old QCS system and – profile control system are updated to meet today's requirements. For this need,this unique co-operation can offer a very competitive solution from an economical, but the especially technical point of view, regardless of the size of a project. Both companies are also in very close relation with several paper machinery, especially headbox manufacturers. This wider co-operation makes it possible to offer entire headbox rebuild with automatic MD & CD controls, QCS and all other needed equipment. Companies are not in competitive relation to each other and then the projects are carried out in close teamwork, targeting to the common goal.

The latest successful project was in July 2019-started KR Paper project in India for 5,4m wide headbox. In that project, Jasch delivered a new on-line measurement frame and – sensors. Tasowheel delivered 80pcs of full stainless steel dilution valves (RDV20) and the same amount of dilution control actuators (RDA2090). Intelligent profile control algorithms were in Jasch scope. Even KR Paper made two orders from two suppliers, the project showed up to them as one entity. Jasch and Tasowheel agreed on the division of the work, schedules, manpower, commission etc. together directly. Project delivery went seamless and trouble free. KR Paper was very satisfied also to results.

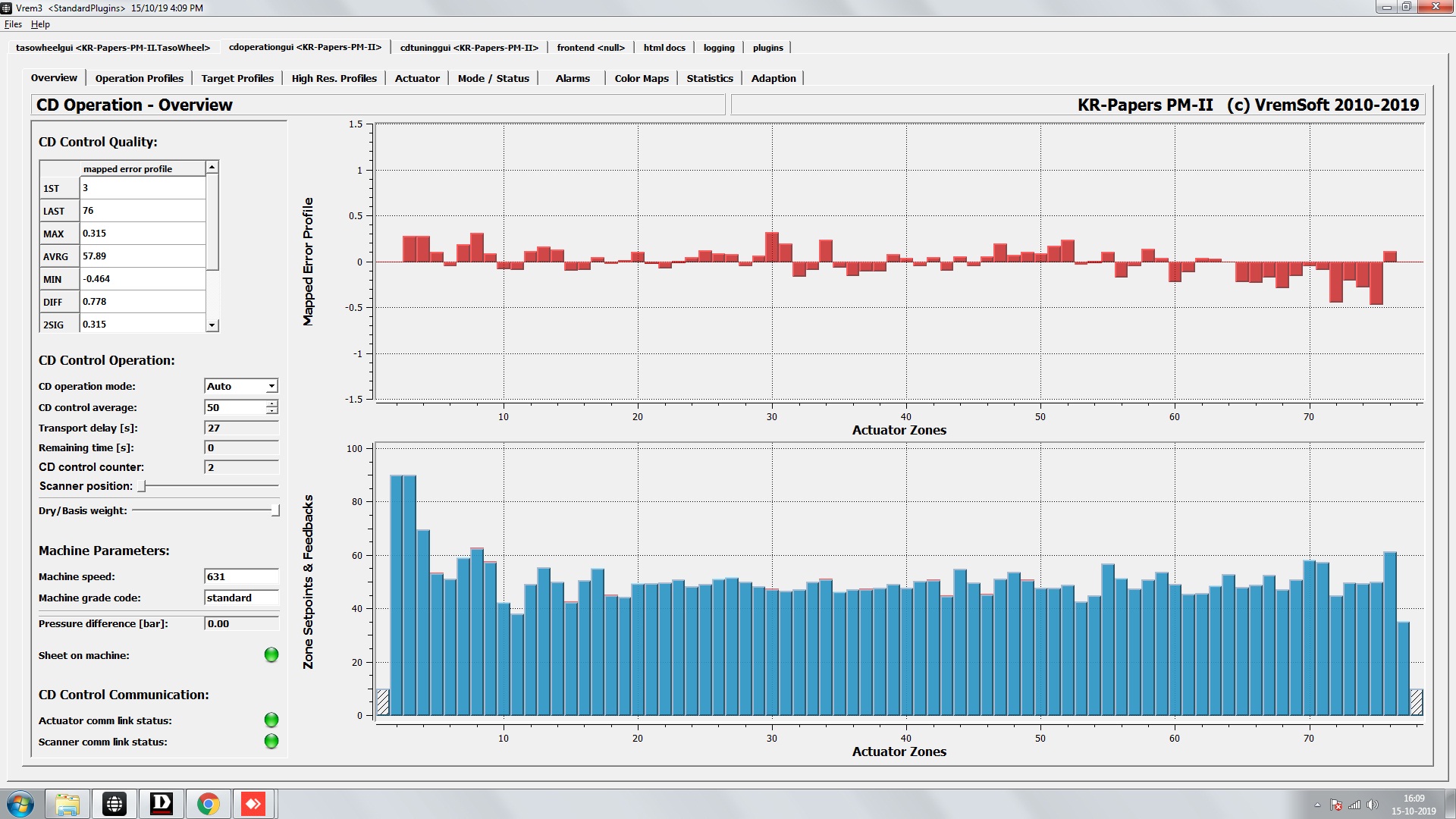

Significant Improvements in paper quality were achieved after using the Basis weight CD profile control system. The erection and commissioning of the complete system was done by Jasch Service Engineer as planned on time. After the machine startup, the cross direction2sigma value of basis weight profile was 5.0 and after the automatic profile control system was started it went down to 0.8 (i.e. 82% improved) within just 5 minutes of operation with edge to edge control by advanced automatic mapping feature. The performance was also measured as per TAPPI TIP 1101-1 standard and the 2 sigma value was found to be below 0.3.

The other benefit as observed were increased machine runnability, reduced downtime with higher production, faster grade changes, reduced waste and better roll winding.

Web Title: Successful Partnerships on QCS Profiler Expertise A Case Study

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)