A new capacity for the multi-grade paper manufacturing in Mandapeta, Andhra Pradesh

A new capacity for the multi-grade paper manufacturing in Mandapeta, Andhra Pradesh

Krishna Prabhas Papers is setting up its first paper machine with 150 TPD capacity.

Mandapeta | 20th January 2022 | The Pulp and Paper Times:

The Indian paper industry was one of the worst hit due to the COVID-19 pandemic outbreak leading to closure of educational establishments, coaching centers, and corporate offices, and adoption of new culture of Work from Home. The sector has witnessed some signs of revival. The closure of educational institutes significantly impacted the demand for paper. Paper manufacturing scenario in India is witnessing a significant shift towards sustainability with large paper mills working to improve efficiencies, increase productivity, and reduce resource intensity.

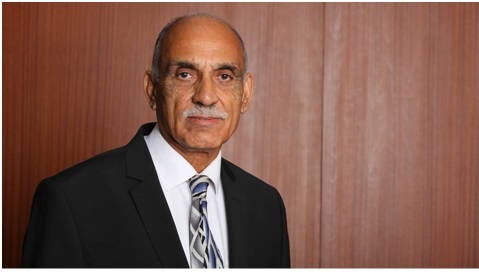

“Paper plays a key role in communication and as a packaging material. Demand for paper is closely linked to the prevalent economic conditions. The paper industry continues to have a reasonably moderate prospect in India during next few years as the demand of paper and paper products grow in line with the GDP growth,” said Mr. Anil Vytla, Executive Director and one of the owners of Krishan Prabhas Papers Pvt. Ltd. (KPPPL).

Exclusively taking to The Pulp and Paper Times, Mr. Vytla discloses his paper manufacturing venture in detail, “We are setting up our first state-of-art paper machinery infrastructure to manufacture different grades of paper. We have invested a considerable amount in installing a 150 TPD machine line, which is likely to be commenced commercially by the end of April 2022.”

Situated at Mandapeta, Andhra Pradesh, KPPPL is also targeting the export market with its paper quality and trust. “We will manufacture Newsprint, Writing & Printing, and low GSM kraft paper on the same machine. Our GSM range for Newsprint and WPP will be 40 to 80, with 72 to 75+ percent brightness. Our raw material will be 100 percent waste paper and imported OCC grade.” He informed.

KPPPL will have finish deckle of 3.47 meters, “we have bought second-hand machinery of Beloit while entire pulp mill section has been supplied by Kadant Inc.” He said.

Taking the current stock of market condition, whereof 3rd wave of COVID impacting the demand of WPP, Schools, and colleges have again gone back to ‘online’, Mr. Vytla says, yes, there has been pressure on WPP demand and we are fully ready to envisage our target by diverting the production to Kraft paper manufacturing also.

“We have made provision in the machinery to produce lighter weight grocery bag kraft paper up to 120 GSM. The lower side GSM for kraft paper will be 70,”

“We are also eyeing the export our 30 percent paper production to various countries, mostly to Africans countries.” He informed.

In WPP segment, KPPPL has no plan to introduce itself as A4 paper seller in the retail market, “we will remain in reel form not in sheet” he said.

On the spike in waste paper prices post lockdown, Mr. Vytla sees the rising shipping prices as a major bottleneck in procuring imported received paper at a cheap price.

As per CRISIL, global demand for writing and printing (W&P) paper, paperboard and newsprint in 2021 is expected to grow by 6-10% on-year after witnessing a steep fall in 2020 due to demand contraction across the globe on account of Covid-19 related disruptions. Paper demand revival in 2021, can be closely ascertained by world GDP growth during the period. According to IMF economic outlook, April 2021 report, world GDP to expand by 6% in 2021 after contracting by 3.3% in 2020

Web Title: A new capacity for the multi-grade paper manufacturing in Mandapeta, Andhra Pradesh

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)