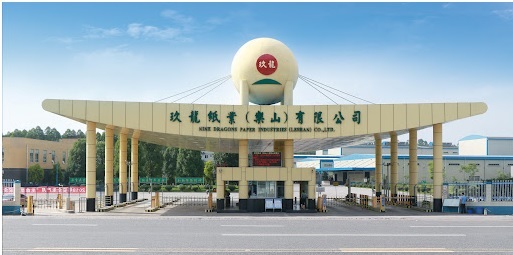

In the face of sluggish market demand, Nine Dragons Paper will continue to develop more product categories

In the face of sluggish market demand, Nine Dragons Paper will continue to develop more product categories

Zero import quota is creating short supply of quality recovered paper in China

China | 2022 | The Pulp and Paper Times:

During FY2022, with the persistent global pandemic and the Russia-Ukraine conflict, the fuel and transportation costs remained at a high level. Given the high inflation rate and the heightened risk of interest rate hikes, the depreciation of Renminbi, the sporadic COVID-19 outbreaks across China with consumption and supply chains disrupted by the lockdown measures, the economy was astonishingly hit.

The pandemic containment measures in mainland China has resulted in shrinking consumption and disruptions to logistics and transportation. The demand for packaging paper remained sluggish. Coupled with the adverse impact of factors such as the surging costs of raw materials, energy and chemicals for paper production, as well as interest rate hikes, profits of the Nine Dragons Paper were under severe pressure.

“In the face of various headwinds, we closely monitored the market development. While actively visiting our customers, we also adjusted our raw material and product mix to cater to the market. As sustaining a healthy level of working capital and cash flow was crucial amid adversity, we have executed “cost reduction and efficiency enhancement” measures and strengthened financial risk management during the Year, which achieved satisfactory outcome. Thanks to our team’s concerted efforts, the sales volume for the Year remained relatively stable while the average price of products increased slightly as compared with that of the previous year. The cost increase of recovered paper, wood pulp and coal, however, was more substantial, and it could hardly be passed on because of the unfavorable market conditions, hence resulting in lower profits year-on-year.” said Ms Cheung Yan Chairlady, Nine Dragons Paper (holdings) Limited in the Annual report for FY 21-22

Ms. Yan further stated that “Transform and see the way out.” As a leading enterprise, we will never rest on our laurels even in times of difficulties. Upon consideration in a holistic manner, we will take active moves and forge ahead despite difficulties. In the face of sluggish market demand, we will continue to develop more product categories that cater to market needs through innovation, which also helps ensure the stable operation of production lines.

Currently, Nine Dragons Paper has a paper production capacity of 18.17 million tonnes with economies of scale. ND Paper exercise prudence in planning to avoid unsound business expansion. Therefore, the investment in every tonne of production capacity has to promote the upgrade of the profit mix. The expansion projects of production bases in Hubei, Beihai, Shenyang and Malaysia are now underway, which are expected to add new production capacity of 6.85 million tonnes in total for virgin kraftlinerboard, bleached folding boxboard and sack kraft paper. As such, The group is making strides towards the goals of raising the proportion of high-margin products and fostering sustainable development in the long run.

Looking globally, all the largest paper making enterprises own their vertically integrated production chain. As a leading enterprise in Asia, Nine Dragons Paper has gradually developed its vertical integration of the production chain, and provided end-customers with one-stop and high-quality products and services by leveraging its competitive advantages.

Ms. Yen stressed upon the thorough implementation of the “zero import quota on recovered paper” policy, the short supply of quality recovered paper in the market has become an issue that needs to be immediately tackled. “In order to alleviate the concern about raw materials and raise the proportion of high-margin products in the long run, we pressed on with the fully-integrated pulp and paper mill projects in Hubei, Liaoning, Guangxi of China and Malaysia to increase the production capacity for wood pulp and recycled pulp. Besides, we made proactive effort in scaling up the production capacity of wood fibre as an alternative raw material to effectively curb the paper manufacturing costs. Upon the successive completion of these projects, it is estimated that an additional production capacity of 3.12 million tonnes for wood pulp, 0.60 million tonnes for recycled pulp and 1.10 million tonnes for wood fibre will be added to the Group, which will further optimize our fibre and raw material mix as well as strengthen upstream capacity.” She added.

Ms. Yen predicts that In view of the current ever-changing pandemic situation and geopolitical risks, coupled with other factors such as the exchange rate volatility, interest rate hike and high inflation rate, uncertainties still cloud the global economic outlook in the near future. However, with the gradual recovery of the industry chain in mainland China and a series of stimulus policy being put in place by the government to stabilize the economy, domestic demand, consumption and the export business will be boosted, which would enable the economy to get back on track. In the mid-to-long term, the trend of replacing plastic with paper in packaging and consumption upgrade will fuel the demand of high-end packaging paper, while the tightened raw material supply and environmental policies will drive consolidation in our industry.

Web Title: In the face of sluggish market demand, Nine Dragons Paper will continue to develop more product categories

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)