Excess of Exports over Imports: The suggestion of providing protection to the domestic paper manufacturers is totally illogical

Excess of Exports over Imports: The suggestion of providing protection to the domestic paper manufacturers is totally illogical

-Domestic paper manufacturers have been taking the domestic customers and users for a ride

-Domestic manufacturers to upgrade their quality as the quality of imported paper and paperboards has been superior to the quality being offered

The below article is written by Mr Aseem Bordia, who has become the 61th president of the Federation of Paper Traders Association (FPTA) for the year 2022-2023. The views are personal; Mr. Bordia shares his views on export of paper, Waste paper scenario, Quality of Indian paper products and the present state of the Indian Paper Industry exclusively with The Pulp and Paper Times. Views are personal.

Indian paper industry even after post-independence has remained one of the most fragmented sectors with production capacity ranging from 5TPD to 1650TPD and geographically dispersed all over the country. The pace of change in upgradation of technology, and plant and machinery has lacked momentum and not kept pace with the global developments.

Globally the impact of Covid was felt. Every sector whether manufacturing, services and or distributive trade faced closure and were forced to stop operations. The entire eco-system of the paper sector growth was hampered.

Import and Export of Paper:

Since last few months a systematic move has been started with a motive of creating a narrative that imports of paper & paperboards have increase multi-fold and thereby there is a need for imposition of safeguard, anti-dumping and countervailing duties on paper imports. In addition, there are demands for issuance of Quality Control Orders (QCO).

It is common sense to make comparisons between two equals (apples with apples and oranges with oranges, and not apples with oranges). The common practice is to quote and compare the data in quantity (metric tons) as it is stable and fixed. The data in amount (Rupees) is variable, based on several internal and external factors like rupee-dollar parity, price movements etc. Such internal and external factors are not adjusted before the data in rupees is compared. This only gives a one-sided picture and is a totally incorrect way of analysing the data without the necessary adjustments being made before comparison. If at all comparison is to be made on the basis of value (rupees and or dollars) then in all fairness provide the month wise chart of Rupee- Dollar parity (according to the value of dollar declared on a monthly basis by the customs department) and month wise price chart (CIF) of the grade being compared. It is then and then only that the actual comparisons would be possible.

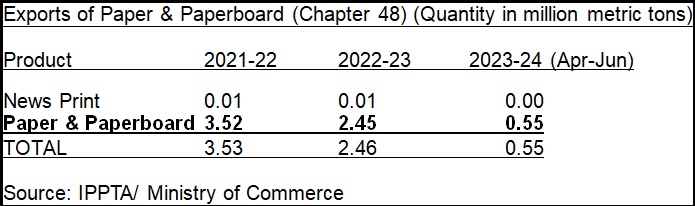

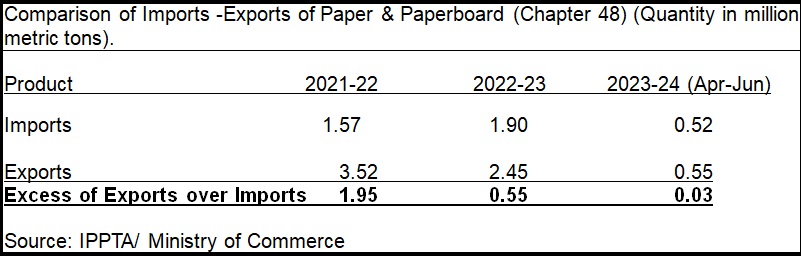

The picture being presented is that imports of paper & paperboard have increased substantially over the last two years and the current year. Here is the true picture:

Reiterating the fact that newsprint paper (ITC: HSN Code 4801) is part of Chapter 48 under the Indian Customs Duty structure, which also includes writing and printing paper. The Government of India has put in place a Newsprint Control Order (NCO) 2004.

It is very clear that the exports of paper and paperboards have been higher in the FY 21-22, FY 22-23 and even in the first quarter of FY23-24.

Paper can be recycled 5-7 times. Every ton of finished paper imported in to the country provides 5-7 times fibre for remaking of paper. This saves the foreign exchange on imports of waste paper. However, in the case of exports, every ton of export of finished paper, indirectly exports 5-7 tons of fibre also. The country has to thus make a higher foreign exchange payout for importing 5-7 tons of waste paper in lieu of every to of exports of finished paper.

Therefore, any suggestion to impose safeguard, anti-dumping and countervailing duty, increasing basic customs duty is devoid of any merit and justification. The suggestion of providing protection to the domestic manufacturers is totally illogical and merits no consideration at all.

The suggestion of having a level playing field, implementation of quality control measures and issuance of quality control orders needs to be taken positively and are a forward-looking step. It is imperative that in order to have a level playing field for the domestic players and importers, to implement quality control measures and issuance of quality control orders for both the domestic players as well as the importers. It is for the domestic manufacturers to upgrade their quality as the quality of imported paper and paperboards has been superior to the quality being offered by the domestic manufacturers. It is also beyond logic that one party does not have any sort of compulsion to meet any quality standards whereas the other party is forced to accept higher norms of quality and even pay for getting approval for the same. Bureau of Indian Standards (BIS) came into formal existence from October 12, 2017, formerly known as Indian Standards Institution (ISI), which existed since 1946. Though tens of standards were framed, adopted and published with the industry’s participation but hardly any quality standards were put to use by the domestic paper sector. Rather it was a of mere academic reference point for discussion. The Quality Control measures and Quality Control Order should be uniform and applicable for both the domestic as well as on imports. The rules of the game should be framed before the start of the game and not midway after the game has started.

The domestic paper manufacturers have been taking the domestic customers and users for a ride even after seventy-five years of independence due to lack of transparency and information. The use of prefixes and suffixes have created more confusion rather than transparency. The industry has failed to standardize the nomenclatures and also failed to provide physical and chemical properties for any grade in its normal course of business.The government should initiate steps in recommending putting an end to the practice of using prefixes and suffixes with the nomenclatures, and bring a statutory provision for publishing quality parameters of each grade/ nomenclature on the website of the manufacturer and sharing of the quality parameters with the customer/ user/ buyer.The government should initiate steps to bring about uniformity in grade/ nomenclature so as to bring about transparency and create a level playing field for the user/ consumer of paper. The quality parameters and nomenclatures should be uniform, irrespective of the raw material used. This would also go a long way in preventing the consumer/ user being charged more for an inferior quality. This step will go in making the user sector more competitive as a result of transparency and availability of information.

The Legal Metrology Act 2009 has come into force from April 1, 2011 replacing The Standard of Weights and Measures Act 1976. Similarly, the Packaged Commodities Rules 1977 under The Standard of Weights and Measures Act 1976 has been replaced by The Legal Metrology (Packaged Commodities) Rules 2011 under The Legal Metrology Act 2009. The domestic paper manufacturers have failed to comply with its provisions. This impacts the consumers/ users negatively and enriches the domestic producers. It is suggested that the government should take notice and seek proper compliance of the provisions of law by the domestic manufacturers of paper and paperboard.

Web Title: Excess of Exports over Imports: suggestion of providing protection to the domestic paper manufacturers is totally illogical

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)