"There will be a demand for good quality Corrugating boxes with consumers willing to pay for the right quality": Harsh Pati Singhania, VCMD-JK Paper

"There will be a demand for good quality Corrugating boxes with consumers willing to pay for the right quality": Harsh Pati Singhania, VCMD- JK Paper

- Don't have any immediate plans to enter into backward integration which is Kraft Paper manufacturing.

- We aim to introduce further products & solutions on new board machine started at CPM.

- We have reduced our water consumption per ton of output by 30% over last 5 years.

JK Paper makes sustainable Paper solutions, from paper which is produced via Social Farm Forestry without harming a single forest tree. Its paper-based solutions are 100% bio-degradable and recyclable which provide a choice of switching to a sustainable future.

In the year 1962, Unit JKPM at Rayagada (Odhisa) was established. Today, JK Paper is a leading Indian player in Office Papers, Coated Papers, Writing and Printing Papers and High-end Packaging Boards.

In India JK Paper service its customers through an extensive distribution network of over 300 trade partners over 4,000 dealers, 15 depots & 4 regional marketing offices.

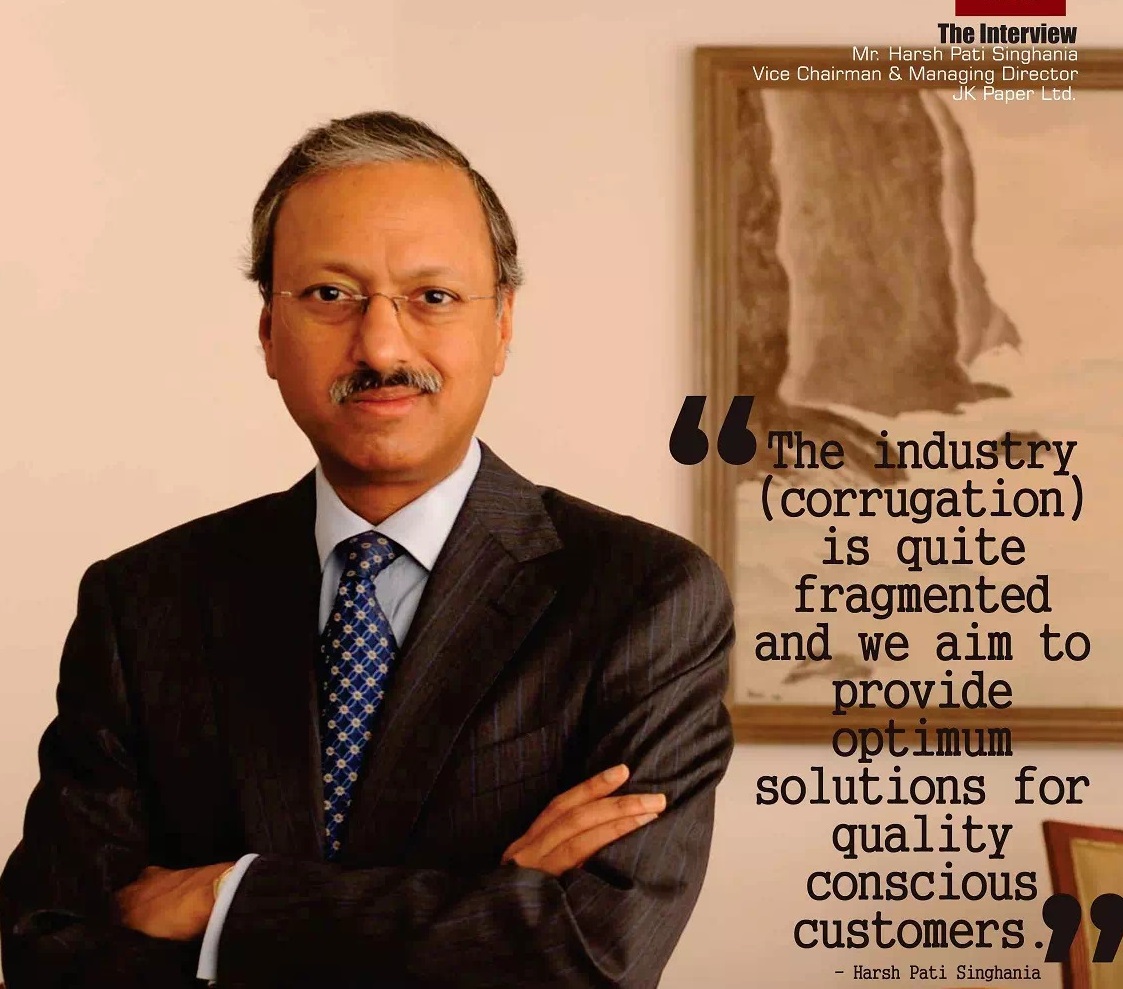

Recently, The Pulp and Paper Times interacts with Mr. Harsh Pati Singhania, Vice-Chairman & Managing Director of JK Paper Ltd. over various developments being carried out on new products in JK Paper and its diversification into the corrugation segment. Here are his views:

25th December 2021 | The Pulp and Paper Times:

Q: What is your quick review on the present condition, post-second wave, markets are opened, and schools & colleges have resumed studies. Do you think the pressure on Writing and Printing paper’s demand would vanish completely in the next three to four months?

With markets, schools & offices opening, we feel that mills should be able to reduce inventories & demand should be back to pre-covid levels. In fact as per an analysis by CARE Ratings, net sales for the major paper companies as whole are up 33% q-o-q and 63% y-o-y in Q2 of current fiscal. Moreover it is up 14% over pre-crisis period in Q2 FY20.

But with the emergence of the new strain of Omicron virus, the market sentiments are turning cautious. Many parents are refraining from sending their children to school resulting in many schools going back to online mode of education. As a result of all this, it may take few more months for Writing Printing demand to return back to pre-Covid levels.

Q: JK Paper intends to widen its product mix, planning to introduce liquid packaging, cigarette board, anti-fungal and aqueous boards. Please throw some lights on your future products.

With expansion at Unit CPM Unit atGujarat & acquisition of Sirpur Paper Mills (SPM) at Telangana, our range of products has increased considerably. Liquid Packaging Board, Cigarette Board,Anti-fungal and AqueousCoated boards are new product opportunities for J K Paper. We have just started our new board machine at CPM and once it is fully optimised, we aim to introduce further products & solutions.

Customers are increasingly interested in fiber based solutions shifting from plastics, coupled with the introduction of government’s push for implementation of plastic waste management. There is also a shift amongst the youth from carbonated to healthy & non-carbonated juices & beverages.

Q: Recently, J K Paper takes a ‘surprising’ decision to invest in the corrugated box manufacturing segment, what factors are working behind this decision? Can we assume that JK would foray into Kraft paper making also in the future?

Our investment in corrugated shipping box manufacturing is based on the growth of this sector arising from need for sustainable packaging solutions and e-commerce. The industry is quite fragmented and we aim to provide optimum solutions for quality conscious customers. While we don’t have any immediate plans to enter into backward integration which is Kraft Paper manufacturing, we will examine suitable options in due course.

Q: The corrugation Segment in the Country is facing raw material shortage, prices are going up, and the waste paper price has not been steady in the past. How do you see this entire scenario, especially when the ‘hike’ is difficult to pass on to the end-user industry in the box segment?

The Waste Paper availability, Container shortage and Kraft Paper Price volatility has affected the Corrugation Industry in recent past. But in the long run,we believe that there will be a demand for good quality Corrugating boxes with consumers willing to pay for the right quality.

Q: India is also an emerging market with nearly 27 million tonnes of additional paper and board requirements by 2030, What is JK Paper's planning to contribute a major portion to this demand?

With the recent major expansion at Unit CPM , acquisition of SPM and various efficiency improvement projects at Unit JKPM, we have increased our capacity to 7.70 lakh ton per annum. Before these expansions, we were a major player in Office Paper, but now we have a very good market presence in Packaging Board and Maplitho as well. We have set up a strong countrywide network of channel partners to ensure extensive reach among printers & publishers and packaging board converters across the country.

We have taken several initiatives which are all geared towards improving customer experience.

Q: What is the situation in the Copier Paper segment, has the demand returned to its full strength? Please throw some light on the export market of writing and printing paper

With offices and schools reopening and gradually coming back to normalcy, Office Paper demand is coming back to pre-Covid levels. This was evident from the fact that the industry saw a significant jump in sales in the months of September and October 2021 though it moderated afterwards due to channel restocking & fulfilment of pent up demand.

We have been aggressively chasing export markets for our copier papers to balance domestic demand. There has been a revival in demand for copier papers globally. Copier exports for the Industry during Apr-Sep21 period of current fiscal has already reached 3.07 lakh tons against 3.61 lakh tons against the whole of last year. If current trends continue, we may even surpass the pre-pandemic levels of 4.7-4.8 lakh tons in FY19 and FY20. In value terms, copier exports by end of Sep 2021 was at about Rs 1,600 crore ($216 million) and most probably exceed the pre-pandemic levels of Rs 2,700-2,900 crore ($400 million).

Q: The procurement of imported waste paper (OCC) is becoming an issue for domestic paper manufacturers, prices are going up and lots of new capacities in Europe and America are ready to start in short while. How do you assess the waste paper crisis?

We are not major users of imported waste paper & hence this doesn’t impact us generally.

Q: Recently, the Government of India has come up with the norms for the enforcement of 'rules of origin' provisions for allowing the preferential rate of customs duties on products imported under free trade agreements. The primary aim of such a policy is to stop the unauthorized benefits and claims of Custom benefits under the respective Trade Agreements like FTA / PTA / CECA / CEPA). How does JK Paper evaluate this kind of imposition, particularly for paper trade? Will this rule benefit the Indian paper industry and discourage the import of paper?

While domestic industry is operating under challenging conditions, substantial quantities of paper and paperboard is imported into the country at significantly lower prices under the aegis of the FTAs. This is because, in a number of countries there are concessions given to the paper industry, including a Forest Wood procurement policy, which provide significant cost advantages to the Paper mills in those countries. Domestic industry has invested huge amounts in the recent past to upgrade and implement clean technology, product quality, agro / farm forestry, etc. and more investments are in the pipeline. Such large investments cannot and should not be jeopardised by allowing imports at concessional / nil rates. In this regard, the new norms for the enforcement of ‘rules of origin’ provisions are welcome. But this is not enough and a review of existing FTAs is called for. This is particularly so as non-tariff barriers impose far more restrictions on trade than applied tariffs.

Q: JK Paper is working on various new products under various stages of development focusing on specialty paper grades, What are these new grades? What impact do you see on the demand of all grades of specialty paper post-COVID pandemic?

Covid pandemic has hastened the level of awareness among consumers for Health, Hygiene and environmentally sustainable solutions. In line with the same, we have been working towards coming up with extensive range paper based solutions as an alternative to plastics based applications because paper is an environment friendly product as it is produced sustainably through Social farm forestry and is completely biodegradable. These are in areas of day to day usage like carry bags, food containers, packaging solutions.

Q: Research and Development (R&D) is a core activity for the advancement of any industry. How JK Paper is promoting R&D in the paper industry, what new steps are being taken by JK Paper?

R & D always have been our focus area in JK Paper. We have our own research institute PAPRI ( Pulp& Paper Research Institute) which is NABL/BIS accredited lab engaged in R & D. Recently we have also entered into a COE with IIT Delhi for Research & Development.

JK Paper has been doing continuous research to come up with high-yield saplings which are provided to farmers to improve their earnings and livelihood. This will go a long way to ensure sustainable future of paper industries in India.

Q: Reduction in Energy consumption is the need of the hour globally. What are the JK Paper's plans to cut down the energy consumption to 50% by 2030?

Energy conservation has been our focus for a long time. 67% of the overall energy consumed in the mill is through renewable energy at Unit JKPM. With modernisation at CPM& SPM, our share of renewable energy will increase there too. We have achieved substantial reduction in energy & water usage at our mills through use of modern technology over the years. We have reduced our water consumption per ton of output by 30% over last 5 years & our coal, electrical energy & water consumption for an integrated pulp & paper mill producing fine paper at Unit JKPM is the lowest in the country & one of the best in global standards. We are continuously investing in energy saving projects & we aim to be lowest consumer of energy & water in all of our mills with technological innovations & collaboration with Academia.

Web Title: There will be a demand for good quality Corrugating boxes with consumers willing to pay for the right quality Harsh Pati Singhania VCMD JK Paper

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs) Join Buy Sell Channel (Free to Submit)

Join Buy Sell Channel (Free to Submit) Paper News Headlines Channel (Free to read)

Paper News Headlines Channel (Free to read)