With the largest deckle, Aksa Paper Mills is going to jostle the Kraft paper market

With the largest deckle, Aksa Paper Mills is going to jostle the Kraft paper market

Vapi | 2nd August 2021 | The Pulp and Paper Times:

India is a country where the labour is very cheap and technology-wise it has great future. Therefore India is a perfect destination for making corrugated boxes. It can be reused, reshaped, foldable, light-weight, cost-effective, comes in various shapes and sizes & it is truly eco-friendly. Thus all these factors add economic value to packaging paper manufacturers.

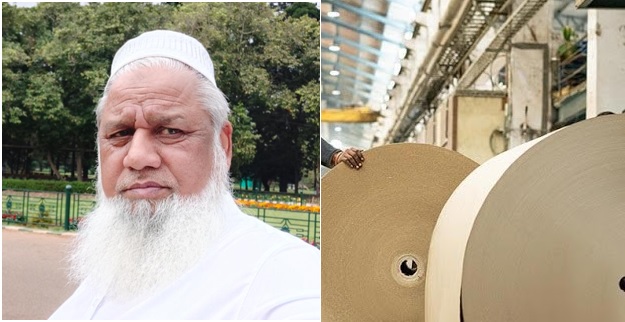

“The corrugated box Industry is an inevitable part of manufacturing sectors which rely heavily on corrugated packaging for finished goods transportation and handling. Asia pacific enjoys the leading position in the global corrugated boxes industry on account of a large consumer base and rapid economic development in countries such as china and India,†said Mr. Ayub Haji Yasin Saiyed, Managing Director, Aksa Paper Mills Private Limited.

Situated at Vapi in Gujarat, Aksa Paper has acquired 6 acre land, for deploying a mega capacity paper production plant with the largest (finished) deckle of 4.8 meters. “Rapid economic growth and sustainability in Kraft paper consumption are the major factors behind our decision to invest approx Rs. 70 to 80 Cr in state-of-art paper production facility. We are expected to start the 300 TPD paper manufacturing by the end 2021,†Mr. Ayub informed.

The construction of building work is in full swing and expects to complete by end of August, “plant and machinery have been arrived at the site and we will start machinery erection process from September onwards,†he said.

“Our aim to choose the largest deckle was to eye on the export market. Our deckle size is most preferable deckle among Chinese importer of paper, we are targeting to export kraft paper to china and other countries,†Mr. Ayub said.

The new paper mill will manufacture 18-32 high BF kraft liner and media paper in the range of 120-300 GSM on double wire machine. The product will be high RCT paper. This Kraft liner is best for corrugated box manufacturing.

Aksa Paper mill has engaged Micro Fab Industries and Parason Machinery for supplying of plant and machinery, “Our machinery is mixed of China and India, and we are importing 50 to 60 percent machinery section from China like dryer, two head box, suction couch roll, and suction press section. We will take wire part (top and bottom), dryer frame, size press from Micro Fab, while pulp mill section to be supplied by Parason machinery†Mr. Ayub informed.

The new mill will have an Effluent treatment plant (ETP) from Krofta Engineering.

On the rising raw material price, which is affecting the viability of a paper mill? Mr. Ayub said, yes waste paper price has exponentially increased post Covid pandemic, consumption of paper is dropped, mall and market were closed for long duration, but Government is control ling the pandemic in the best way. Finished paper price has also been increased in proportion to waste paper’s price.

Corrugated board boxes are used in different area of packing in goods such as breweries, glass wares, cigarettes, Pharmaceuticals, Biscuits, Milk & Milk products, soap, Cosmetics, Tea & Coffee, Hosiery, Shoe & Footwear industry, toys etc. So likewise the market size of corrugated boxes in India is very big and has a great growth potential especially after the ban of plastic packaging. This has poised to drive the demand of corrugated Board packaging. Factors such as increasing demand from fresh food and beverages, home & personal care goods, electronic goods industries, logistics application, increasing consumer awareness towards sustainable packaging and growth of the e-commerce industry have propelled the growth of Indian corrugated boxes market and it is expected to grow more in the future.

Web Title: With the largest deckle Aksa Paper Mills is going to jostle the Kraft paper market

More News From india

Next Stories

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs)