Investments in corrugation industry by large corporates may trigger the much-awaited consolidation in future

Investments in corrugation industry by large corporates may trigger the much-awaited consolidation in future

- Paper Mills and Corrugators have to survive with each other and not at the cost of each other

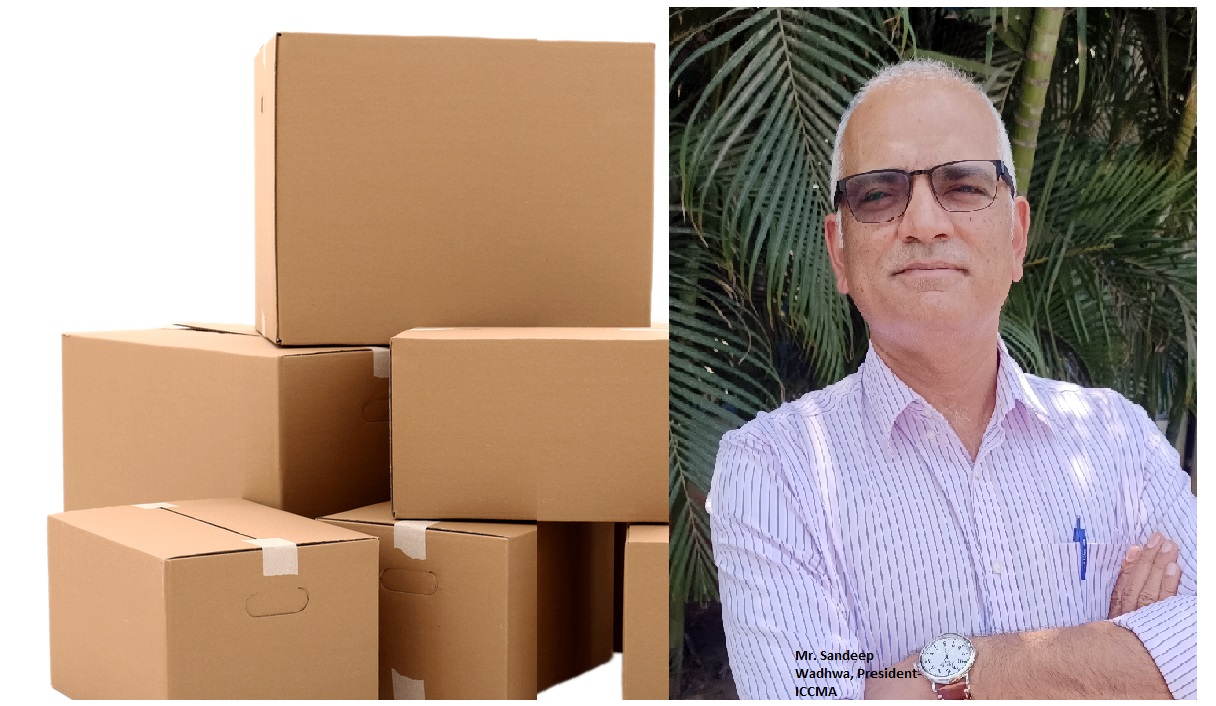

Indian Corrugated Case Manufacturers’ Association (ICCMA) is a new national association in the corrugated paper packaging industry. ICCMA will aim to give more attention to the need for effective partnership between the Government and the corrugated packaging industry. It is dedicated to strengthening the independent's position in the marketplace through programs and publications that empower its members to compete successfully in a rapidly changing industry and an increasingly competitive and global business environment.

Recently, The Pulp and Paper Times got the opportunity to having an exclusive interview of ICCMA’s president Mr. Sanjay Rajgarhia over various issues related to the paper and corrugation industry. Here is his full interview:

June 2022 | The Pulp and Paper Times:

Please give a brief introduction of Indian Corrugated Case Manufacturers Association (ICCMA) for our Readers.

ICCMA was founded in 2009. During the early 2000s there has been a sea change in the technology and scale of operations and Investment in the Corrugated Industry. This change was adopted by few players in the Industry by setting up automatic corrugated board-making lines and it was felt that the issues and concerns they faced were very different from those of the traditional corrugated box making plants. Hence this difference in ideology led to formation of a new Corrugated Industry Body called ICCMA. At present we have 213 members from all across the Country. The criteria for admission to the Association is that the members/applicants must have an automatic corrugating line installation. ICCMA Governing Council then vets the application for approval. ICCMA GC has appointed regional coordinators from amongst themselves to look into regional issues whereas national issues are looked into by the full Governing Council. We hold an annual conference alternately in Delhi NCR and Mumbai which provides a meeting ground for Corrugators, Paper Mills, Machinery and spare parts suppliers.

Q: What is ICCMA’s quick review for the present raw material crisis both for corrugators and Paper Mills?

During the last year there was a severe crisis of Waste Paper due to lot of external factors and hence a huge jump in their prices . Indian Waste paper also mirrored the price increase and there was a huge cost increase for the Paper Mills which they passed on to the Corrugated Industry . Since March ’22 the situation has eased and supply and pricing seem to be stabilizing as of now .However , India being a Fibre deficient country and having significant reliance on imports is very easily affected by overseas developments including increased recycling by overseas mills, additional pulp and paper capacities and shipping containers availability and pricing. These supply-side dynamics cause market volatility and the industry would need to live with it.

Q: As per market analysis, the imported OCC price is expected to surge upto $450 to $500 per ton by the end of 2022, the reasons behind this are obvious, E-commerce boom in Europe, New capacities of about 4 million tonnes in packaging paper thus low export of the imported OCC, uptick freight charges, and lower consumption of writing printing paper is led to drop in the waste paper collection. What will be ICCMA’s strategy/suggestion for its members in order to remain secure on the margin front and as well raw material?

It is very difficult to put a number on the expected OCC pricing and neither would we as an Association like to hazard a guess on the same. However as said earlier we are very susceptible to international developments and feel that supply and price volatility is here to stay for a while at least. We would advise our members to be careful before entering into long-term contracts with their valued customers and at same time maintain regular purchases and inventory of raw material and refrain from speculative overstocking or panic buying.

Q: In March this year, For seeking a hike in box prices in order to remain viable, Corrugators are closing down their operation for a week or shortening the operating hours across India. Did it bring the desired results? Second, passing the hike over to the end-user industry, can there be a way by which corrugators may insist to the end-user to buy paper for them at whatever the market price, so that any up and down in the price of paper will be borne by the end-user themselves.

We are not aware of any Corrugators intentionally cutting down their operations/production to get price hikes. In fact, Corrugators have borne huge Kraft paper price hikes and incurred heavy losses to sustain the supply chain due to the time lag between cost increase and box price increase by customers. On the second point….buying paper by the end -user would not only be a very tedious and complicated process, but also it entails risks for brand-owners as paper stocks are lying with box-makers, and they are wary of taking such risks going by the painful experiences in the past..Moreover, when a Corrugator buys paper, he combines the requirements of various customers and places the order with the mills to economize on deckle, freight etc . If an end user were to buy paper they would have to manage the inventory of their particular requirements which may or may not be a full truckload or suit the deckle of the mills . Also, there would be a dispute between the corrugators and end-user in case of any quality problems. The viable solution would be to have a periodic review of the paper prices and implement the same on pre-decided dates without delay.

Q:The associations related to paper and corrugations are seeking the Government's intervention in the raw material crisis. What are ICCMA’s demands? Do you think the Government can really regulate the prices and excessive export of Kraft paper in the open market dynamics?

ICCMA has not sought any Government intervention in the raw material crisis . We have represented to the Government that export of Pulp Rolls should be banned . After China banned import of waste paper in 2021 , Indian mills starting importing waste and pulping it and converting it into rolls and exporting to China . These Pulp rolls were used by Chinese mills for re-pulping to by-pass &beat their own waste paper import ban . Thus Indian mills were helping Chinese mills using our scare fibre ( to some extent ) and also precious resources like water , energy and also causing pollution , which China was clamping down upon . In short we were a LAUNDROMAT for China . ……………… .

We don’t believe that Government can regulate prices. ICCMA feels, at this point of time, that Govt. should monitor/regulate export of Pulp rolls. Exports of other grades of Kraft paper may be left to market forces. However, if such exports impact domestic availability of fibre critically, then Govt. may decide to review the same in future.

Q: Recently, A big Paper Mill – JK Paper has stepped into the corrugation segment investing INR 150 crores for box making with the latest technology. How does ICCMA review this move, especially when the majority of the corrugated box manufacturers are small and medium entrepreneurs?

The Indian Corrugated box industry is highly fragmented with most players in small and medium sector. There is already excess capacity in the Industry and resultant poor bargaining power at both ends of the supply chain . We have to wait and see how JK Paper approaches these issues and overcomes these challenges. Of course the technology and financial clout will give them an edge. Such investments by large corporates may trigger the much-awaited consolidation in the Industry in future with the entry of large players

Q: As a newly elected president of ICCMA, Where do you see your association in the next ten years? What are the various weak areas in the operation of conversion, where you feel that attention is required in order to make the Indian corrugation industry a better and more efficient Industry in the International Domain?

ICCMA’s primary objective is to further the cause of the Corrugated Industry , provide a platform to its members to interact on common issues and also impart education to the members. The agenda for each year is set by the Governing Council which normally consists of 13 members, with due regional representation. ICCMA will continue to play this role in the years to come and also expects enhanced membership so as to be able to serve the Industry better.

The main weak areas in conversion are lack of standardization in the raw material viz Kraft Paper and non-availability of skilled labour . At the ICCMA level we have made some attempts to address these issues . However lot of work is required to be done to overcome these issues

Q: What is the current growth rate of the corrugation industry in India, and how will it take shape in the next five years?

As a thumb rule the Corrugated Industry grows at 1.5 times the GDP growth . Going by this trend the growth rate would be in the region of 12%. Because of the highly fragmented nature of the Industry we do not have authenticated data to validate this. Various factors like Make in India initiatives by the Govt, PLI schemes, growth of E-Commerce segment, Increasing exports and India’s favourable demographics should ensure a doubling of the Corrugated Box demand in 5 years .

Q: This present scenario is already being challenged by the sweeping changes that are beginning to take shape. More and more in-line automatic plants are being set up and corrugated box makers are gearing up to meet the new demands for high-precision boxes with attractive graphics, and large integrated production capacities. Amid this, how will MSME corrugators transform themselves with small capital and liquidity crunch? What kind of support ICCMA does provide to MSME box makers?

As stated above ICCMA only provides a platform for members to interact or takes up common pressing issues and does not provide support to Individual members as such. Large investments are coming in the Industry and but there is demand for all types of boxes and the demand is also expected to grow . There may be some consolidation in the Industry and some unviable units may shut down…that is natural in any Industry. I personally believe that the semi-automatic plants would need to upgrade their quality sooner rather than later and they should invest in converting equipment and source board from nearby automatic plants . This would address a lot of issues like upgradation of box quality, minimal investment in fixed assets as well as Working capital for semi-auto plants and simultaneously better capacity utilization of the auto-board plants .

Q: Research & Development is a core exercise to develop a value-added product for the end-consumers securing product margin. How do you evaluate the R & D activity being conducted by ICCMA's member companies? If we see the last decade of corrugation operations, what major R & D outputs have been delivered to the end consumer market?

R&D activities are carried out by members based on their or their customers’ individual needs and ICCMA is not privy to the same . Generally speaking, one major output has been use of High RCT paper to get the desired Compression strength in the boxes with reduced paper weight . Again , these are individual exercises and ICCMA does not have any data on the same . R & D activities need various resources - financial, human, infra-structure etc and to generate the same needs reasonable profit margins, which unfortunately are not adequate to help the units in the industry to pursue.

Q: Increasing demands of Kraft Paper suppliers to specify RCT ( Ring Crush Test) instead of BF & adhere to it consistently. Box manufacturers have started differentiating mills on the basis of consistent quality. How would ICCMA evaluate the Kraft paper quality of the Indian Paper Mills on various parameters?

Box makers have become very conscious about the quality of the paper they buy because it not only affects their final box quality but also their productivity and hence cost of production . ICCMA does not directly evaluate the quality of Indian Paper Mills but did organize various webinars/workshops to educate its’ members about the importance of various quality parameters.

Q: Any special message for Indian Paper Mills you would like to convey?

Paper mills need to focus on standardization of their grades as well as quality parameters and partner with Corrugated Industry to find win-win solutions . There is need for greater interaction and understanding of issues faced by corrugators. Price stability &visibility of paper is very important for the overall financial health of both Paper Mills and Corrugators. I am not talking of price level….i am referring to reducing volatility and developing a mechanism for price stability. Paper Mills and Corrugators have to survive with each other and not at the cost of each other .

Web Title: Investments in corrugation industry by large corporates may trigger the much-awaited consolidation in future

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs)