Naini Group Invests Rs. 1035 Cr. To Stand In Premium Packaging Segment

Naini Group Invests Rs. 1035 Cr. To Stand In Premium Packaging Segment; 1,50,000 TPA Packaging Grade Capacity To Run By 2021

Kashipur | 20 February 2019| The Pulp and Paper Times:

"The global fibre based packaging market has witnessed extraordinary growth over the past few decades on account of numerous applications of fibre-based packaging across several end-use industries. The emergence of modern retail formats where the visual appeal, shelf life and unique brand identity have taken the centre stage. Paperboard packaging offers all these advantages and more – it is consumer-friendly, provides excellent product protection, is lightweight, easy to transport & stack and easy to dispose of," explained by Mr. Pawan Agarwal, Managing Director at Naini Papers Limited.

"We are very excited to foray into Premium Packaging grade manufacturing like Folding Box board (FBB), Solid bleached board (SBB) and Liquid packaging board, which will help us to stand in wood-based fibre packaging production in the country. The demand of eco-friendly packaging solutions, Fibre-based packaging utilizes biodegradable material obtained from natural sources that are sustainable in the long run. Yes, we have decided to install a separate modern packaging grade production line of 1,50,000 TPA capacity which is expected to be operational by March 2021," Mr. Agarwal exclusively revealed to The Pulp and Paper Times.

Mr. Agarwal further discloses his plan that “for procuring wood pulp, both for Writing Printing and Packaging paper board production, we have selected Valmet to deliver the key process technology for a new cooking, fiber line and recausticizing plant, as well as a new lime kiln, at Naini Papers. The new plant is expected to produce approximately 100,000 tons bleached hardwood pulp per year, and start-up is scheduled by the end of the first quarter in 2020,â€

From Valmet's viewpoint, NK Jain, Sales Director, Asia-Pacific Pulp & Energy, explains that there are several important factors that led to Naini selecting Valmet. "In this project, we are able to utilize our strong presence in India, our local supply and our state-of-the-art TwinRoll press technology. These advantages helped us earn the customer's trust as a reliable and experienced leader in pulping processes."

Naini Papers is gearing up to invest a huge amount of money for wood Pulp line, Packaging line, Captive power plant, effluent treatment plant and other critical components. “Naini Group takes immense pride in its ability to adopt latest technologies be it in the field of process, environment, energy & water conservation, plant maintenance, product development, and system development, for maintaining the highest level of Quality Standards, we will not compromise on account investment deployment; it may be the largest investment in wood-based packaging. Naini Papers has arranged a sum of Rs. 1,035 crore as a capital investment, to be spent gradually in the next two years,†said Mr. Agarwal.

Liquid packaging board is a multi-ply paperboard with high stiffness, strong wet sizing and a high barrier coating, e.g. plastic. Only virgin paper fibres are used. The barrier coating must hold the liquid and prevent migration of air and flavours through the paperboard.

“We are aiming to manufacture 160 to 450 GSM range packaging board based on wood pulp as well as Bleached Chemical Thermal Mechanical Pulp (BCTMP) which is to be imported from Europe and Canada. We are now in the process of finalising the Plant & Machinery supplier's name and are expected to have it in our order book by June 2019,†told Mr. Agarwal.

The machine will be engulfed with the deckle of 3.8 meters (finished) and 500 m/m speed. “The installation process of plant and machinery is expected to be over by January or February 2021, by then only we will proceed for trial production,†Mr. Agarwal informed. Naini will target to export 25 percent of packaging paper board, once commercially operated.

Naini Paper will also install a 16 MW captive power plant to keep the power expenses in control.

“Naini Group believes strongly in environmental ethics and hence keeps abreast with the standards set to bring sustainable development. It has been a wonderful journey in breaking the challenges and making new paths towards the glory of success. We are looking forward to a harmonious relationship and cooperation from our stakeholders and all members of Naini family, to help us reach greater feats in the years to come,†Mr. Agarwal concluded.

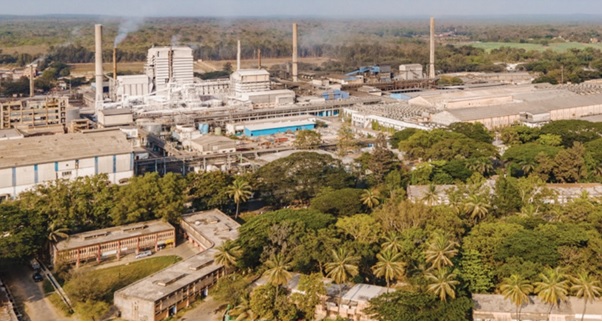

Naini Papers Limited, which was started in 1995, is one of the few premier paper manufacturing facilities in India.

Naini offers high-quality writing and printing papers with improved physical and optical properties.

The Naini plant is equipped with a modern wet washing system, continuous digester, oxygen de-lignification plant and multi-stage bleaching.

Information about Pulp Line

The batch cooking and fiber line delivery includes a digester plant consisting of three conical bottom digesters, and a fiber line comprised of seven Valmet TwinRoll presses, screen room, MC pumps, mixers and tower scrapers, as well as the basic engineering and site services. The re-causticizing delivery also includes one OptiDisc(TM) WL.

The new long wet lime kiln has a design capacity of 200 tons per day, with a chain system for drying of the lime mud inside the kiln. The kiln will be supplied with a burner system designed for either firing producer gas in combination with furnace oil or alternatively firing 100% furnace oil. The producer gas is a low temperature, low-grade gas produced in a coal gasifier.

Solid bleached board (SBB / SBS)

SBS is considered as premium grades for packaging and graphical purposes in FMCG Industry (Typically high-end personal care and cosmetic brands). Being a 100% virgin fibre board, SBS is the preferred choice for food packaging applications like paper cups and liquid packaging. It is made up of bleached chemical pulp coated with mineral or synthetic pigments on top and sometimes on the reverse side, thus this coated back makes it well suited for book covers and greeting cards which require back side printing. This grade of paperboard has high brightness, smoothness and superior surface and printing characteristics. It has a surface brightness of 90% ISO.

Folding box board (FBB)

This board comprises middle layers of mechanical pulp sandwiched between layers of bleached chemical pulp. The mechanical pulp at the centre makes the board stiffer as compared to SBS. The top and reverse sides of this board may be coated with mineral or synthetic pigments. As the bleached chemical pulp layer is translucent the reverse side of the board appears cream (or manila) in colour. However, if the mechanical pulp in the middle layers is given a mild chemical treatment, it becomes lighter in colour and this makes the reverse side colour lighter in shade.

The reverse side layer may be coated with a white mineral pigment coating, thus becoming a white back folding box board. Similar to SBS, FBB is produced from virgin fibres and is suitable for food packaging applications. It is considered ideal for cigarettes, cosmetics, pharmaceuticals and graphical applications. In India, FBB is the primary grade of packaging substrate used by most of the companies.

Web Title: Naini Group Invests Rs 1035 Cr To Stand In Premium Packaging Segment

Join WhatsApp Group

Join WhatsApp Group Join Telegram Channel

Join Telegram Channel Join YouTube Channel

Join YouTube Channel Join Job Channel (View | Submit Jobs)

Join Job Channel (View | Submit Jobs)